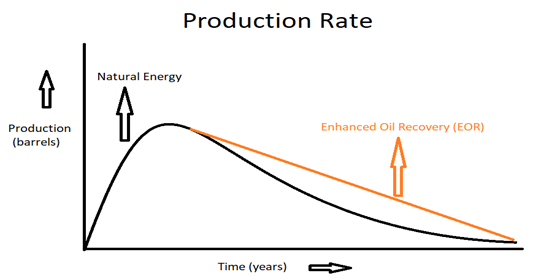

EOR stands for Enhanced Oil Recovery. It is a tertiary oil recovery technique that can be applied at any stage during the production of a reservoir to restore the lost formation pressure and to improve fluid flow in the reservoir. Reservoir pressure declines with due course of production from a reservoir which leads to a low rate of production. EOR technique is used to increase the pressure of the reservoir again to enhance the production rate ultimately.

Understanding Oil Recovery Process:

Oil recovery from the reservoirs is carried out in a phased manner. Primary recovery is the first phase of production that involves natural drive mechanism followed by secondary and tertiary recovery techniques.

Primary recovery is based on the initial reservoir pressure conditions. Recovery is made through natural energy present in the reservoir without applying any external energy. The mechanism incorporates the pressure difference between producing well bottom and reservoir pressure.

In secondary recovery, which is followed by primary recovery, the pressure of the reservoir is restored by providing external energy. When natural reservoir drive is depleted, and the production rate starts declining, either gas or water is injected into the reservoir through an injection well to lift the pressure of a reservoir. It is commonly known as "Waterflooding" if the reservoir is supplied with water through injection. The recovery efficiency may vary from 10-40 per cent.

After primary and secondary recovery phases, tertiary recovery techniques are used to recover the remaining pore-scale accumulated oil in the reservoir. EOR techniques usually can extract more than half of the total OOIP (Original Oil In Place).

Source: Kalkine Group Image

Understanding EOR:

EOR being a more expensive method, it is used after the completion of primary and secondary recovery techniques and it can increase the production by up to 70 per cent. It is a sophisticated technique that changes the actual properties of hydrocarbons distinguishing it from primary and secondary recovery practices.

Injection of water or gas in secondary recovery is used to push the hydrocarbons into the well whereas, in tertiary recovery injected gas and water changes the properties of oil in fields that exhibit low permeability, heavy oil and irregular geological faults.

There are three main types of EOR recovery techniques which include chemical flooding, gas injection and thermal recovery.

Chemical Injection:

Chemical Flooding technique is recommended for depleted and flooded formations. Various type of chemicals, including surfactants, polymers, alkalis etc., are poured into the reservoir based on the previously obtained laboratory pilot results. Addition of surfactants and alkali can reduce the interfacial tension between brine and oil, which can improve the microscopic sweep efficiency. On the other hand, the addition of polymer will increase the viscosity of the aqueous phase leading to improved macroscopic displacement. Addition of surfactants improves microscopic displacement efficiency by reducing oil-water interfacial tension.

Gas Injection:

As a tertiary recovery method, gas injection technique uses natural gas, nitrogen or carbon dioxide. Gas is injected into the reservoir to displace oil towards the production well. The success of the method is based on displacement and sweep efficiency. Carbon dioxide is the most common gas used for the recovery technique and accounts for over 50 per cent of the total operations. This is the best technique to produce incremental oil.

Thermal Recovery:

The principle of the thermal recovery process is generally based on increasing the reservoir temperature to decrease the viscosity of the oil, which ultimately provides improved mobility. This technique is mainly used in heavy and viscous oil formations and is considered the best & effective process for extracting heavy oil reservoirs. Steam Flooding is applied in the reservoirs to decrease the oil viscosity, improving production rates. It is considered as the best method for surging production.

Environmental Impacts of EOR:

An enormous amount of produced water is injected into the reservoir. The produced water contains brine along with other toxic heavy metals and radioactive substances. This can affect groundwater quality if not appropriately controlled. Disposal wells are generally used to prevent surface contamination of water and soil by injecting the produced water deep into the underground.

One ongoing method that may help diminish these natural dangers is called plasma pulsing. Created in Russia, plasma pulsing technology includes emanating oil fields with low-energy discharges, along these lines bringing down their viscosity much like other EOR techniques.

Please wait processing your request...

Please wait processing your request...